เรามาทำความรู้จัก ระบบพ่นหมอกจากละอองน้ำ (ที่ต่างประเทศใช้คำว่า Misting) กันหน่อยดีมะครับ

บ้านเราส่วนใหญ่มีการนำมาใช้ร่วมกับพัดลมเรียกว่า พัดลมไอน้ำ จริงๆ น่าจะเรียกว่าพัดลมละอองน้ำ น่าจะเหมาะกว่า ถ้าท่านยังจำได้สมัยเรียน ไอ กับ ละออง นี่มันต่างกันอย่างสิ้นเชิงเลยนะ ส่วนตัวผมเข้าใจว่า ไอเกิดจากของร้อน ส่วนละอองเกิดจากของเย็น เข้าใจง่ายหน่อย

ทำไมเราต้องการละอองน้ำขนาดเล็ก มันมีประโยชน์อะไร?

ผมเขียนตามความเข้าใจของผมเองนะครับ ก็มาจากความรู้เล็กๆ น้อยๆ จากหลายๆ ที่

มันเป็นเรื่องของการถ่ายเทความร้อนและคุณสมบัติที่ดีของน้ำ ที่มีสูตรทางวิทยาศาสตร์ว่า H2O แปลว่า ไฮโดรเจน 2 อะตอม รวมกับออกซิเจน 1 อะตอม กลายเป็นน้ำ และถ้าทำน้ำให้มีขนาดเล็กๆๆๆๆๆๆๆๆๆๆๆๆๆๆ ยิ่งเล็กๆๆๆๆๆๆๆๆๆๆๆๆๆๆๆๆๆๆๆ เท่าไหร่ก็จะสามารถใช้คุณสมบัติของ ไฮโดรเจนและออกซิเจน ได้มากขึ้น ตอนนี้เรากำลังพูดถึงของชิ้นเล็กๆ แบบเล็กสุดๆ ที่ภาษาวิชาการเรียกว่าอนุภาค คุณคงรู้เหมือนกับผมว่าอากาศก็คือส่วนผสมของอนุภาคขนาดเล็กมากมายหลายชนิด ที่ไม่สามารถมองเห็นด้วยตาเปล่า ซึ่งในอนุภาคพวกนี้ก็มีความร้อนกับความเย็นแฝงอยู่ข้างใน วันไหนอากาศร้อนก็แปลว่ามีความร้อนแฝงอยู่ในอนุภาคของกาอาศมากกว่าความเย็น วันไหนอากาศเย็นก็แปลว่ามีความเย็นแฝงอยู่ในอนุภาคของกาอาศมากกว่าความร้อน ทีนี้ ถ้าเราต้องการทำให้อากาศร้อนกลายเป็นอากาศเย็นเราต้องมีอนุภาคขนาดเล็กพอๆ กับอนุภาคของอากาศ มาเป็นตัวกลางให้ความร้อนไหลผ่านออกจากอากาศมาสู่ตัวกลางตัวนี้ แล้วตัวกลางตัวนี้ก็เปลี่ยนสภาพไปตามสภาวะของมัน ซึ่งการเปลี่ยนสภาพของอนุภาคต่างๆ เมื่อได้รับความร้อนจะเป็นไปตามขั้นตอนนี้ จากของแข็ง กลายเป็นของเหลว จากของเหลวกลายเป็นไอ(มองเห็นด้วยตาหรือไม่ก็ได้) ให้นึกถึงน้ำแข็ง วางไว้บนฝ่ามือ จะค่อยๆ ละลายกลายเป็นน้ำเย็น ความร้อนจากฝ่ามือถ่ายเทไปหาน้ำเรื่อยๆ น้ำเย็นกลายเป็นน้ำเย็นน้อยลง ยังคงให้น้ำอยู่บนฝ่ามือต่อ ความร้อนจากฝ่ามือและอากาศจะค่อยๆถ่ายเทมาที่น้ำ ผิวนอกของน้ำจะค่อยๆ "ระเหิด" กลายเป็นไอที่คุณมองไม่เห็น แต่จะสังเกตุได้ว่าน้ำจะค่อยๆ หมดไปทีละนิด ขั้นตอนนี้จะดำเนินไปเรื่อยๆ จนกระทั่งน้ำบนฝ่ามือคุณไม่เหลือแม้แต่หยดเดียว(ซึ่งมันนานมาก ถ้าคุณอึดพอนะ อิอิ)

สิ่งที่น่าสนใจจากตัวอย่างที่ยกมาคือ การระเหิดได้ของน้ำในสภาวะอุณภูมิปกติ แปลว่า อนุภาคน้ำขนาดเล็กๆๆๆๆๆๆ (น้ำที่ผิวของน้ำบนฝ่ามือ) เป็นตัวกลางถ่ายเทความร้อนจากอากาศได้ดีและปลอดภัยไม่มีมลภาวะ ซึ่งจะทำให้อากาศร้อน กลายเป็นอากาศเย็นได้อย่างปลอดภัย และข้อดีอีกอย่างของอนุภาคน้ำก็คือมีความชื้นในตัวและสามารถจับตัวกับสิ่งแปลกปลอมในอากาศได้ดี เช่น กลิ่น ฝุ่นละออง สารเคมี ฯลฯ ที่ไม่มีในอากาศปกตินะ

แล้วเราจะทำให้น้ำมีขนาดเล็กลงได้ยังไง ?

หลักการสร้างละอองหมอกขนาดเล็กจากน้ำเย็น(อุณหภูมิปกติ)

ไม่ได้ซับซ้อนอะไรเลย หลักการเดียวกับการทุบหินให้ละเอียดนะแหละ คือ คุณต้องมีฆ้อนที่แข็งแรง มีพื้นสำหรับวางก้อนหินที่แข็งกว่าก้อนหินที่จะทุบ และมีก้อนหิน เมื่อมีครบแล้วก็แค่เอาฆ้อนทุบลงไปที่ก้อนหินด้วยท่าทางที่ถูกต้องก็เท่านั้นแหละ

ที่นี่สำหรับน้ำ ฆ้อนก็คือปั๊มความดันสูง พื้นสำหรับวางก้อนหินก็คือหัวพ่นหมอก ที่ทำมาจากวัสดุที่ไม่เกิดสนิม ส่วนท่าทางที่ถูกต้องในการทุบก็คือกลไกและขนาดของรูที่หัวพ่นหมอก ถ้ามีสามอย่างนี้ก็สามารถทำให้น้ำมีขนาดเล็กลงได้ไม่ต่างอะไรกับก้อนหินที่ถูกทุบ

ขั้นตอนการทำละอองหมอก

น้ำจะถูกดูดผ่านปั๊มอากาศความดันสูง น้ำและอากาศความดันสูงจะเคลื่อนไปตามสายหรือท่อสำหรับงานความดันสูง และถูกดันออกมาทางหัวพ่นหมอกตามทิศทางของกลไกภายในหัวพ่น จะได้ละอองน้ำขนาดเล็ก(ตามขนาดของรูที่หัวพ่น) จำนวนมาก โดยใช้น้ำเพียงน้อยนิด ที่มองด้วยตาเปล่าจะมีลักษณะคล้ายหมอกหรือไอน้ำ ที่เหลือก็คือการประยุกต์ใช้งานไอ้เจ้าละอองน้ำละเอียดพวกนี้ให้เหมาะกับงานต่างๆ

EZE Fog 24/7 :: 083-020-3936

อีซี่ฟ็อก พัดลมไอน้ำ ราวพ่นหมอก หัวพ่นหมอก ระบบพ่นหมอกจากละอองน้ำ สัญชาติไทย อะไหล่นำเข้า หลากหลายประโยชน์ใช้งาน ไม่ใช่แค่ทำความเย็นในร่มโล่งแจ้งหรือกลางแจ้งเท่านั้น ยังสามารถประยุกต์ใช้งานได้หลากหลายในทุกสถานที่ จากคุณสมบัติของละอองน้ำละเอียดเหมือนหมอก

ส่วนประกอบ EZE Fog

ระบบพ่นหมอก ราวพ่นหมอก ผลงาน EZE Fog ในไทย

ที่ท่านเห็นในรูป เป็นงานระบบพ่นไอน้ำ ผมเรียกระบบพ่นละอองน้ำละกันนะ งานพืชพันธ์ไม้งามของชาวอาชีวะที่ปทุมธานี งานนี้ยากพอควร เพราะไฮไลท์ของงานคือสวนทิวลิป ที่ต้องแสดงในงาน 5 วัน ทิวลิปต้องไม่เหี่ยว เราทำได้ สวยด้วย ขอบอก ไครสนใจจะใช้บริการของเราก็ติดต่อมาคุยกันก่อนได้นะครับ ปรึกษาหารือ ตลอด 24/7 ที่เบอร์ 081-362-5933 หรือ 083-020-3936 นพรุจ กิตติธรารัฐ(ณะ) ครับผม

Dust Control

Dust Suppression

Dust SuppressionTrueFog, USA Dust Suppression System brings state-of-the-art technology to the difficult and costly task of controlling dust at manufacturing, industrial and agricultural sites. It produces a ultra-fine water fog that effectively attracts and holds dust particles so that they can be more readily removed from the work place and other environmentally sensitive areas. In a typical application,

TrueFog can serve as an auxiliary unit to cyclones, making them much more efficient, and earning, where applicable, emission reduction credits. TrueFog can also deliver highly effective odor neutralizing agents.

Low Initial Cost. Low Operating & Maintenance Cost. Operating at 800 PSI, TrueFog requires no costly air compressors, making the initial outlay lower than a ventilation type control system. TrueFog can be installed for as little as 60% of the conventional bag filter type system. It can operate on as little as five percent of the total energy of a conventional system.

TrueFog is delivered at .018 gallons (of water) per nozzle per minute. In a typical situation—.05 grams of dust per cubic foot of airspace - there would be, at any given moment, 210 times more water particles than dust particles (this is assuming both have the same density).

Cooler Temperatures, Higher Productivity. TrueFog also provides cooler temperatures in hot, dry outdoor situations, improving worker productivity. Inexpensive to operate, lightweight and compact, the system can be set up in a few hours, quickly providing a safer, more comfortable environment while reducing labor costs.

The TrueFog Dust Suppression System can be a big money saver. Water consumption averages only 1.08 gallons per hour per nozzle. Operating cost, depending on the size of the system, can be as low as 20 cents an hour, water and electricity combined.

Reduces PM-10 levels in open plant areas by 50% or more - Will remove much of the finer dust particles - Safer than bag houses. No fire hazard - Can be used in high humidity conditions - Cools workers on jobs where hot-dry air is a part of work environment - Traps dust particles without over-wetting material.

Each TrueFog Dust Suppression System is custom designed to catch and suppress dust in the most effective way at any given site. The atomization nozzle and delivery system create a 10-micron fog droplet without using a air compressor, resulting in exceptionally cost effective PM-10 suppression. Lightweight, compact, minimum of interference with plant and worker activity and easily installed.

Completely automated operation programmable up to 24 hours. TrueFog can also Injects surfactants (making water wetter by 50%) to better attract and hold dust particles.

TrueFog is highly effective in PM-10 suppression and can create a safer, more comfortable environment in a wide range of situations.

Outdoor Cooling

Outdoor Cooling Specialist's

Outdoor Cooling Specialist'sAny number of companies can sell you an outdoor cooling system, but very few have the expertise, the experience, the commitment it takes to sell you a system designed just for your application. We have installed TrueFog systems for many national and multi-national companies. As a full service manufacturer supplier, TrueFog is uniquely qualified to analyze and fulfill your outdoor cooling requirements.

We offer a comprehensive product line, allowing you to tailor a system to your particular needs. We back our sales with a complete list of value added services, including, custom engineering services and computer aided design.

Most important, we approach every customer relationship with commitment to quality and service that's unmatched in the industry. We invite you to evaluate our company on these important criteria:

Quality Assurance. Every system we build is designed and manufactured to the industry's highest standards.

Reputation. Our leadership in our field is based on years of experience, quality products, superior service and lasting performance. The first system we built is still in operation today.

Design. With more than 1000 systems manufactured and installed our experience and specialization are your assurance of absolute design integrity in your new outdoor cooling system.

Manufacturing. Every step in the manufacture of your system is meticulously controlled through installation and final inspection.

Efficiency. Mechanical and hydraulic design features are combined to provide high efficiency, peak performance for lower operating costs.

Consultation. Engineering oriented sales personnel are always available to assist you with your system selection and design.

Responsibility. In addition to product quality, premium performance, and service before and after the sale, TrueFog offers a degree of responsibility to customers you won't find else where. TrueFog assures you undivided responsibility in all its transactions.

Residential & Commercial Applications

In-stucco Outdoor Cooling Systems

TrueFog, The world leader in industrial climate control technology and the original manufacturer of the stainless steel TrueFog outdoor cooling system, has developed this attractive high quality system designed to be installed on new construction projects and is available only from TrueFog and its authorized dealers.

The TrueFog in-stucco system includes our exclusive stainless steel fog line capable of operating up to 1000 PSI with a burst pressure of 20,000 PSI. The TrueFog in-stucco system is the most advanced form of outdoor cooling available, when properly designed and installed, it can reduce outdoor temperature up to 30 percent. TrueFog has proven effective in more than Three Thousand installations around the world. You can depend on TrueFog for engineering and design excellence.

The TrueFog In-stucco outdoor cooling system is fully guaranteed for five years and is installed by our professional factory-trained installers.

The TrueFog In-stucco system is designed to allow the fog line and supply lines to be concealed from view while improving performance, serviceability and durability.

WOOD STORAGE

.jpg) WOOD STORAGE

WOOD STORAGEHUMIDIFICATION PROBLEM

Inconsistencies in humidity and temperature levels affect wood in storage and during production cycles. Wide "swings" in these levels cause warping and cracking of the unprocessed wood, and slowing production through computerized machinery. Automated paint application is more difficult in lower humidity.

SOLUTION

TrueFog, USA® humidification systems have the solution. Using computerized sensors and controls, a level and constant humidity can be maintained in the factory or store area. Typical humidity levels of 35% in the paint room and 80% in the storage area are maintained ± 1% at all times. TrueFog, USA® fog nozzles are installed on flexible or rigid stainless steel fog lines throughout the factory to provide fine fog and humidity control. A fan system ensures proper air movement

WINE BARREL

WINE BARREL

HUMIDIFICATION PROBLEM

Wine makers throughout the world have always suffered large losses in barrel rooms due to low humidity levels. The "New World" wines from the Americas and the Southern Hemisphere have not had the benefit of large underground wine cellars with naturally high humidity levels. They have had to move to modern-day constructions and create artificial environments resulting in humidity levels as low as 5%. Wines in barrel rooms can lose up to 15% volume through the barrel over a two-year period due to fluctuations in humidity levels. "Topping-Off" is an exhausting and time-consuming process to replace these losses. Oak barrels in use or in store suffer from the swings in humidity and can be damaged even before use.

SOLUTION

TrueFog, USA has specifically developed this humidification system for wineries and barrel rooms. Expertly designed, these tailor-made systems are installed in the barrel room to accurately maintain the humidity level to around 85%. Flexible nozzle lines are mounted in the storage warehouse to give an equal distribution of the humidity. The system leaves no wetting of the floors or barrels when in operation and does not affect the stored wine.

The Vintner's Choice computer control system integrates with the air handler and fan systems to create a complete energy efficient environmental control system for wineries. The TrueFog system humidifies and cools the barrel room reducing losses to 1 or 2% per year, drastically reducing the labor involved in "Topping-Off". Applicable in all aspects of Viniculture and Eniculture the TrueFog system's return on investment is as low as one year.

HUMIDIFICATION PROBLEM

Wine makers throughout the world have always suffered large losses in barrel rooms due to low humidity levels. The "New World" wines from the Americas and the Southern Hemisphere have not had the benefit of large underground wine cellars with naturally high humidity levels. They have had to move to modern-day constructions and create artificial environments resulting in humidity levels as low as 5%. Wines in barrel rooms can lose up to 15% volume through the barrel over a two-year period due to fluctuations in humidity levels. "Topping-Off" is an exhausting and time-consuming process to replace these losses. Oak barrels in use or in store suffer from the swings in humidity and can be damaged even before use.

SOLUTION

TrueFog, USA has specifically developed this humidification system for wineries and barrel rooms. Expertly designed, these tailor-made systems are installed in the barrel room to accurately maintain the humidity level to around 85%. Flexible nozzle lines are mounted in the storage warehouse to give an equal distribution of the humidity. The system leaves no wetting of the floors or barrels when in operation and does not affect the stored wine.

The Vintner's Choice computer control system integrates with the air handler and fan systems to create a complete energy efficient environmental control system for wineries. The TrueFog system humidifies and cools the barrel room reducing losses to 1 or 2% per year, drastically reducing the labor involved in "Topping-Off". Applicable in all aspects of Viniculture and Eniculture the TrueFog system's return on investment is as low as one year.

COLD STORAGE

COLD STORAGE

HUMIDIFICATION PROBLEM

In chilling rooms and cold storage treatment of the air with conditioning units depresses the humidity to unacceptable levels, causing plants, vegetables and fruits to dehydrate, lose weight and deteriorate more rapidly.

SOLUTION

Our engineers can accurately calculate water requirements in individual rooms and design a high pressure fog system around those needs. A computer controller accurately monitors and corrects the humidity levels by staging the fog operation. Easily and quickly installed by owners, this system offers a low cost, low maintenance alternative to conventional systems. Smaller, more compact systems for meat and flower storage areas are also available.

BAKERY

BAKERY HUMIDIFICATION PROBLEM

Traditional humidification systems were damaging the bread, resulting in a loss of up to 20% of production.

SOLUTION

TrueFog has solved the problem of economically proofing sourdough bread in bakeries. Utilizing sophisticated humidity controllers and the TrueFog "Fog Box", an ultra fine high pressure, 1 micron fog can be injected into the air to control the humidity.There is no wetting of the bread or the floors and less proofing time is required to achieve a 100% uniformity in the bread.Control systems allow multiple proofing rooms to be set for different humidities at different times of the day.Using no air, only water at 1,000 PSI, the system is quiet and unobtrusive. In some cases, the return on investment for this system has been as little as six months. The TrueFog "Fog Box" system comes with complete installation and operating instructions and is very simple to self install. Additional equipment is also available to cool personnel within the bakery.

Traditional humidification systems were damaging the bread, resulting in a loss of up to 20% of production.

SOLUTION

TrueFog has solved the problem of economically proofing sourdough bread in bakeries. Utilizing sophisticated humidity controllers and the TrueFog "Fog Box", an ultra fine high pressure, 1 micron fog can be injected into the air to control the humidity.There is no wetting of the bread or the floors and less proofing time is required to achieve a 100% uniformity in the bread.Control systems allow multiple proofing rooms to be set for different humidities at different times of the day.Using no air, only water at 1,000 PSI, the system is quiet and unobtrusive. In some cases, the return on investment for this system has been as little as six months. The TrueFog "Fog Box" system comes with complete installation and operating instructions and is very simple to self install. Additional equipment is also available to cool personnel within the bakery.

Paper and textiles

Paper and textiles

PROBLEM

Paper and textiles can suffer from static electricity and poor moisture stability.

SOLUTION

The TrueFog, USA Humidity Control systems are an inexpensive, cost effective solution to cooling and humidifying factories throughout the world.Using The TrueFog, USA high pressure fog system raises the relative humidity level as high at 95% without wetting, while reducing static electricity and (PM10) fugitive dust particles.

PROBLEM

Paper and textiles can suffer from static electricity and poor moisture stability.

SOLUTION

The TrueFog, USA Humidity Control systems are an inexpensive, cost effective solution to cooling and humidifying factories throughout the world.Using The TrueFog, USA high pressure fog system raises the relative humidity level as high at 95% without wetting, while reducing static electricity and (PM10) fugitive dust particles.

INDUSTRIAL COOLING

INDUSTRIAL COOLINGPROBLEM

Overheating of equipment causes equipment failure and production line downtime.

Overheating of equipment causes equipment failure and production line downtime. SOLUTION

TrueFog technology provides optimum temperature and humidity control to keep equipment running at optimum levels. Custom designed systems can be configured for warehouse, plant and factory applications.

TrueFog technology provides optimum temperature and humidity control to keep equipment running at optimum levels. Custom designed systems can be configured for warehouse, plant and factory applications. PRE-COOLING

Condenser Coil Cooling

PRE-COOLINGPROBLEM

In extreme heat, many conventional air conditioners will be shut down or will fail due to excessive ambient loads on the condensing coil. Engineers have attempted to solve this problem by spraying the coil with city water only to find out that this causes calcification and deterioration of the coil. Calcification reduces the heat transfer efficiency and increases operating costs.

SOLUTIONTrueFog offers a solution that "pre-cools" the air as it enters the unit. As a result, the unit operates more efficiently by lowering head pressures which extends its operating life. By coupling the TrueFog system to the condenser coil unit, the system will only turn on when the A/C unit is under heavy ambient loads.Experience has shown that the TrueFog system is an energy saving device that can reduce electrical consumption and not damage the condenser coils. Ongoing tests with utility companies are being performed to verify the efficiency improvements of the system in varying conditions.

Applications:

Movie Complexes

Shopping Centers

Airport Terminals

Communications Switching Stations

Resorts

Factories

Casinos

Hospitals

Commercial Buildings

Convention Centers

Hotels

Manufacturing Plants

Warehouses

Government Buildings

Military Bases

Office Complexes

Schools

Movie Complexes

Shopping Centers

Airport Terminals

Communications Switching Stations

Resorts

Factories

Casinos

Hospitals

Commercial Buildings

Convention Centers

Hotels

Manufacturing Plants

Warehouses

Government Buildings

Military Bases

Office Complexes

Schools

Greenhouse

To promote faster growth, increase yields, improve quality and reduce diseases. As a professional grower you know, that it is vital to monitor and control all environmental factors that can affect your crop.

To promote faster growth, increase yields, improve quality and reduce diseases. As a professional grower you know, that it is vital to monitor and control all environmental factors that can affect your crop. Some of the most important environmental ingredients are optimum humidity levels, maximum light levels, ideal temperatures and reduced disease rates. One environmental control technology has proven itself more than any other, in commercial use, to successfully control and improve all of these vital environmental factors. It is the TrueFog climate control system.

The TrueFog system will provide you and your crop with the following Benefits.

Improvements in plant quality and uniformity.

Reduced stress on plants by eliminating the excesses in temperature and humidity.

Increased germination -- tests show up to 98% germination after 3-4 days with fog.

Increased productivity with more usable plugs and seedlings per crop.

Up to 95% relative humidity without condensation can be achieved.

Humidity levels will be uniform throughout your greenhouse and precisely controlled. In the winter, TrueFog will prevent your crop dehydrating from the effects of your heating system.

In the summer, plant growth and production will slow down or stop when the temperatures exceed 85 or 90°F or when the humidity is lower than 40% or higher than 85%. TrueFog can eliminate the "peaks" and "troughs" experienced without an effective climate control system. With these excesses eliminated the plant has more time to grow and produce valuable fruit. In some cases TrueFog can make a greenhouse profitable in the summer where before it was closed due to temperature and humidity excesses!

In the summer, plant growth and production will slow down or stop when the temperatures exceed 85 or 90°F or when the humidity is lower than 40% or higher than 85%. TrueFog can eliminate the "peaks" and "troughs" experienced without an effective climate control system. With these excesses eliminated the plant has more time to grow and produce valuable fruit. In some cases TrueFog can make a greenhouse profitable in the summer where before it was closed due to temperature and humidity excesses!

In mechanically ventilated greenhouses TrueFog will dramatically reduce summer temperatures. TrueFog creates an artificial fog by atomizing water into 10 micron size droplets that suspend in the air before "flash" evaporating, leaving none of the "hot spots" at the ends of the structure that cooling pads are known for. The temperature drop that can be achieved will vary according to the evaporative potential of the incoming air. Reductions of up to 30°F (16°C) have been achieved. A realistic target figure is Wet Bulb temperature plus 3°F. Compared to the traditional "pad and fan" method of cooling, TrueFog delivers lower temperatures and most importantly temperature and humidity gradients are eliminated. Pad usage is in some cases eliminated or cut in half, a big energy saver. TrueFog systems also provide uniform cooling and humidification in all types of naturally ventilated greenhouses.

TrueFog is ideal for all those specialized growing situations, propagation, germination, rooting, tissue culture and especially for plug production. Leading University reports all confirm that a high pressure fogging system is virtually mandatory for plug production, achieving a high success rate with rapid growth. The high humidity created by TrueFog will allow a higher level of oxygen to get to the rooting structure of the plug, a major factor in successful propagation.

Many diseases are water related. By providing the required humidity in the atmosphere, traditional low pressure misting and irrigation can be cut back. Transpiration rates will decrease and the risk of water related diseases, such as Crown Rot or stem rot is substantially reduced. With a proportional chemical injector, TrueFog can also be used very effectively to instantly distribute throughout your greenhouse any fully water soluble insecticide or fungicide, substantially reducing labor and operating costs.

TrueFog is ideal for all those specialized growing situations, propagation, germination, rooting, tissue culture and especially for plug production. Leading University reports all confirm that a high pressure fogging system is virtually mandatory for plug production, achieving a high success rate with rapid growth. The high humidity created by TrueFog will allow a higher level of oxygen to get to the rooting structure of the plug, a major factor in successful propagation.

Many diseases are water related. By providing the required humidity in the atmosphere, traditional low pressure misting and irrigation can be cut back. Transpiration rates will decrease and the risk of water related diseases, such as Crown Rot or stem rot is substantially reduced. With a proportional chemical injector, TrueFog can also be used very effectively to instantly distribute throughout your greenhouse any fully water soluble insecticide or fungicide, substantially reducing labor and operating costs.

For growers operating without heaters, in winter, TrueFog can act as a thermal blanket to provide a degree of frost protection. In a severe freeze, frost damage to the plant tissue will be reduced.

The TrueFog high pressure fogging system has many unique features and benefits. These include custom sizing, easy grower installation, reliable stainless steel/bronze fitted nozzles producing droplets under 10 micron, anti-drip valves on each nozzle, automatic drain and flush valves, a wide range of high quality pump/motor combinations and triple filtration. If you have poor quality water, optional water treatment systems are available to prevent nozzle blockage. The TrueFog system is designed for minimal maintenance and TrueFog specializes in worldwide service after the sale.

Some of the key components and options of the TrueFog system are:

ATOMIZATION NOZZLE

Produces superfine, 10 micron water droplets and 0.008" nozzle orifice. 10 micron droplets are 1/10 of the diameter of a human hair!. Unique spring-and-ball check valve prevents the nozzle from dripping after the system has satisfied the temperature / humidity requirement.

Unique spring-and-ball check valve prevents the nozzle from dripping after the system has satisfied the temperature / humidity requirement.

TRUEFLEX AND STAINLESS STEEL FOG LINE

Your choice of flexible atomization hose or rigid stainless steel fog line is custom designed and pre-assembled to meet your exact greenhouse specification. Installation is simple and fast. Isolation and drain valves in each fog line, controls the fog level for seasonal conditions.

Installation is simple and fast. Isolation and drain valves in each fog line, controls the fog level for seasonal conditions.

Produces superfine, 10 micron water droplets and 0.008" nozzle orifice. 10 micron droplets are 1/10 of the diameter of a human hair!.

Unique spring-and-ball check valve prevents the nozzle from dripping after the system has satisfied the temperature / humidity requirement.

Unique spring-and-ball check valve prevents the nozzle from dripping after the system has satisfied the temperature / humidity requirement.TRUEFLEX AND STAINLESS STEEL FOG LINE

Your choice of flexible atomization hose or rigid stainless steel fog line is custom designed and pre-assembled to meet your exact greenhouse specification.

Installation is simple and fast. Isolation and drain valves in each fog line, controls the fog level for seasonal conditions.

Installation is simple and fast. Isolation and drain valves in each fog line, controls the fog level for seasonal conditions. PUMP MODULES

Belt and direct-drive pump modules operate at between 800 and 1,200 PSI. The range of TrueFog pump features and options include, low inlet water pressure and high temperature water protection, fused 24 volt controls. Available in 6 sizes with nozzle capacity from 10 up to 1,350.

Our Programmable Logic Control centers allow for the complete control of all necessary functions for proper operation of the Truefog system within the greenhouse application. This equipment is designed for use with Technical (RO) water with all wetted surfaces made of 316 stainless steel and include every imaginable option for safe and reliable operation in any environment or application. The wide range of the Advanced TrueFog industrial quality pump modules features and options include;

Our Programmable Logic Control centers allow for the complete control of all necessary functions for proper operation of the Truefog system within the greenhouse application. This equipment is designed for use with Technical (RO) water with all wetted surfaces made of 316 stainless steel and include every imaginable option for safe and reliable operation in any environment or application. The wide range of the Advanced TrueFog industrial quality pump modules features and options include;

Temperature Set Level ControlHumidification Set Level Control Automated Zone Control (Multiple)Wind Speed ControlWind Direction ControlIntermittent On/Off Timed ControlChemical Injection Feed Pump ControlEmergency Shut OffLow Water Shut Down (Pump Protection)World-Wide PC Ethernet Control Of All FunctionsE-mail System Status to Pager, Cell Phone or PC

Belt and direct-drive pump modules operate at between 800 and 1,200 PSI. The range of TrueFog pump features and options include, low inlet water pressure and high temperature water protection, fused 24 volt controls. Available in 6 sizes with nozzle capacity from 10 up to 1,350.

Our Programmable Logic Control centers allow for the complete control of all necessary functions for proper operation of the Truefog system within the greenhouse application. This equipment is designed for use with Technical (RO) water with all wetted surfaces made of 316 stainless steel and include every imaginable option for safe and reliable operation in any environment or application. The wide range of the Advanced TrueFog industrial quality pump modules features and options include;

Our Programmable Logic Control centers allow for the complete control of all necessary functions for proper operation of the Truefog system within the greenhouse application. This equipment is designed for use with Technical (RO) water with all wetted surfaces made of 316 stainless steel and include every imaginable option for safe and reliable operation in any environment or application. The wide range of the Advanced TrueFog industrial quality pump modules features and options include;Temperature Set Level ControlHumidification Set Level Control Automated Zone Control (Multiple)Wind Speed ControlWind Direction ControlIntermittent On/Off Timed ControlChemical Injection Feed Pump ControlEmergency Shut OffLow Water Shut Down (Pump Protection)World-Wide PC Ethernet Control Of All FunctionsE-mail System Status to Pager, Cell Phone or PC

TEMPERATURE AND HUMIDITY CONTROL

With the TrueFog, USA Computerized controller, now, you can save labor, save energy, save water, and produce the best possible product, all with one compact, state-of-the-art environmental controller.

The Grower's Choice automates on/off equipment (fans, pumps, heaters, TrueFog USA - fogging systems and irrigation valves), and proportional devices too (vents, curtains, valves, etc.). Virtually any device can be precisely controlled with GROWER'S CHOICE. This low-cost unit controls up to 24 different functions and can integrate zone information with outdoor information. The Grower's Choice gives you the precision you need in your controlled environment at a very competitive price, making it ideal for small to medium single-zone operations.

The Grower's Choice automates on/off equipment (fans, pumps, heaters, TrueFog USA - fogging systems and irrigation valves), and proportional devices too (vents, curtains, valves, etc.). Virtually any device can be precisely controlled with GROWER'S CHOICE. This low-cost unit controls up to 24 different functions and can integrate zone information with outdoor information. The Grower's Choice gives you the precision you need in your controlled environment at a very competitive price, making it ideal for small to medium single-zone operations. The TrueFog GROWER'S CHOICE is the SMART CHOICE! For All you flow control needs. PLEASE CALL OR E-MAIL FOR MORE INFORMATION......Key Benefits of the TrueFog, USA - GROWER'S CHOICE CONTROLLEREverything you need is included for one low price.TrueFog, USA brings modern technology to your business for improved quality control and energy efficiency. Your controllers can be networked at a later time if you desire. The Grower's Choice is the Affordable Choice.

Greenhouse report

The TrueFog Industrial Climate Control System uses very high water pressure and specifically designed nozzles placed at precise intervals to give you the optimum humidity level for your greenhouse application. The entire system including high pressure pump, stainless steel tubing and brass nozzles can be adapted to any greenhouse. Since each system is built to your specific needs, the TrueFog System can be altered for use on various individual applications.

APPLICATION:

One of the most important factors that the greenhouse manager must be concerned with is stress to your plants. Usually plants will encounter water stress as a result of being exposed to conditions which include improper humidity levels in relation to temperature.

A plant has tiny openings on the surface of the leaves called stomata. Proper functioning of these openings is imperative to the plant's overall health. The stomata are responsible for all water evaporation from the plant as well as all carbon dioxide/oxygen exchange which is necessary for the plant to grow.

When the temperature in the greenhouse is hotter and there is low humidity, the following chain reaction will occur. The air, with lower humidity, will draw moisture out of the plant via the stomata. At first this will help distribute the nutrients from the soil through the roots and throughout the body of the plant. Eventually, though, the plants moisture level will drop too low and as a defense, the plant will close the stomata to retain moisture and prevent additional water loss. While the stomata are closed, no carbon dioxide is absorbed. This in turn impedes the growth of the plant by stopping photosynthesis and will eventually cause the plant to wilt.

With the TrueFog Industrial Climate Control System, the appropriate humidity levels can be attained and thus the surrounding air will be cooled by the evaporating fog. Since the level of humidity in the air will be higher, the humidity exchange from the plant via evaporation will be lessened. As a result, the stomata will stay open which allows for the essential carbon dioxide/oxygen exchange to take place which, in turn, allows the plant to grow and eliminates dangerous plant wilting.

Although humidity and temperature factors are important, the plants optimum health will also depend on light as well as CO2 levels. The light quality in a greenhouse can be affected by the common greenhouse practice of whitewashing the glass to lessen the exposure of direct sunlight and help maintain lower temperatures.

Whitewashing does help with lowering the temperature associated with long exposure to summer sunlight. However it also lowers the quality of UV light reaching the plant's surface.

A greenhouse is the most effective way to control the plant's environment. However, the appropriate systems must be provided into the mix to maintain the most desirable plant growing conditions. The TrueFog Industrial Climate Control System works in several ways to create this optimum environment.

First, it cools the air. As the artificial fog evaporates, heat calories are extracted from the dry air in the process. The cool air is heavier than the hotter air and thus will fall. The hotter air, like that in a hot air balloon will rise. This exchange of hot and cold air creates proper vertical ventilation and brings more CO2 into contact with the stomata and facilitates the carbon dioxide / oxygen exchange much faster than stagnant air.

By adding humidity to the air, the TrueFog System will decrease the humidity variance between the air and plant thus lowering the demand for moisture from the plant from the air. This will drastically lower the plant's water stress and allow it to grow properly.

Lastly, by cooling the air as well as refracting some of the light which enters the greenhouse, the need for white washing will be reduced or eliminated while still allowing quality light at the proper levels to reach the plant.

By using the TrueFog Industrial Climate Control System, your plants will receive all of the above benefits of a controlled environment. When the conditions are kept at constant optimum levels, the plants stomata will stay open for longer amounts of time to absorb more carbon dioxide causing them to grow faster.

The main differences between the TrueFog System and the common alternative which is a pad and fan system are vast. The pad and fan method uses a fan to blow air over a sponge-like pad saturated with water. In theory, the fan causes the water to evaporate and circulates the moist air throughout the greenhouse. The problem with this system, however, is that it can cause some areas away from the pad to not receive much moisture while areas close to the pad will get perhaps too much moisture which can cause fungal growth. This problem can be lessened by increasing the number of pads and fans throughout the greenhouse but this solution can increase your costs and maintenance time.

The TrueFog System on the other hand, distributes the moisture-rich air evenly through the entire growing area. Also, since the system is installed overhead, mostly all of the fog droplets have evaporated before reaching the plant surface. Thus, the desired effect is reached, the cooler air falls creating the vital vertical mixing of air which facilitates the CO2 exchange, and in turn, growth.

Some problems associated with the system include condensation within the greenhouse, if the output of the system is not balanced with natural climate changes in the greenhouse. Condensation occurs when the overall temperature in the greenhouse cools in relation to the humidity in the air. This can occur in the evening and overnight while the sun is down. If the air is full of humidity and the temperature is not hot enough for it to evaporate, the moisture will fall and collect on surfaces in the form of condensation.

This problem can also be easily avoided by running the climate control system on a timed setting to release the most moisture during times of higher heat and lower humidity and release no humidity as the greenhouse temperature lowers to the point where it can no longer evaporate the moisture output.

Another problem that the greenhouse manager must consider is nozzle blockage. Nozzle blockage is a result of water mineral deposit build-up. This can be easily corrected however, by a mineral deposit inhibitor which is run through the system at scheduled intervals to clear out the deposits in the nozzles. Also, the high pressure with which our TrueFog System operates allows for longer periods of time between removal of the mineral build-up than many conventional misting modules available on the market today. The water is forced through the nozzles at such a high rate of pressure it is more difficult for the deposits to accumulate in relation to some models which are attached to simple pumps which operate at a lower efficiency rate. At any rate, individual nozzles are relatively inexpensive, and can be easily replaced without major disruption of the TrueFog System's Functioning.

Lastly, for the TrueFog Industrial Climate Control System to work efficiently and as it is intended, the greenhouse must be in areas where humidity of the outside air is generally average to low. Remember, the system requires that the air be relatively dry for the fog to evaporate while still in the air.

In speaking to many greenhouse managers and owners, I have noticed a large percentage are concerned with possible difficulties in operating such a large investment. With so many variables to consider-temperature, humidity, light, carbon dioxide, oxygen, many are concerned with experiencing complications in getting the mix just right. However, once the system is installed and operational, and after some minor adjustments during early operation, the system basically runs itself. Scheduled maintenance is recommended and should be performed regularly to keep your system running smoothly.

Even with these concerns, the greenhouse manager will realize that the TrueFog Industrial Climate Control System is capable of a wide range of uses and can correct many environmental problems that you may be experiencing now. It's relatively simple maintenance and inexpensive upkeep as well as it's various applications should prove that most greenhouses will benefit by the use of a TrueFog System. By managing the system effectively it can produce an overall positive effect on your entire crop.

APPLICATION:

One of the most important factors that the greenhouse manager must be concerned with is stress to your plants. Usually plants will encounter water stress as a result of being exposed to conditions which include improper humidity levels in relation to temperature.

A plant has tiny openings on the surface of the leaves called stomata. Proper functioning of these openings is imperative to the plant's overall health. The stomata are responsible for all water evaporation from the plant as well as all carbon dioxide/oxygen exchange which is necessary for the plant to grow.

When the temperature in the greenhouse is hotter and there is low humidity, the following chain reaction will occur. The air, with lower humidity, will draw moisture out of the plant via the stomata. At first this will help distribute the nutrients from the soil through the roots and throughout the body of the plant. Eventually, though, the plants moisture level will drop too low and as a defense, the plant will close the stomata to retain moisture and prevent additional water loss. While the stomata are closed, no carbon dioxide is absorbed. This in turn impedes the growth of the plant by stopping photosynthesis and will eventually cause the plant to wilt.

With the TrueFog Industrial Climate Control System, the appropriate humidity levels can be attained and thus the surrounding air will be cooled by the evaporating fog. Since the level of humidity in the air will be higher, the humidity exchange from the plant via evaporation will be lessened. As a result, the stomata will stay open which allows for the essential carbon dioxide/oxygen exchange to take place which, in turn, allows the plant to grow and eliminates dangerous plant wilting.

Although humidity and temperature factors are important, the plants optimum health will also depend on light as well as CO2 levels. The light quality in a greenhouse can be affected by the common greenhouse practice of whitewashing the glass to lessen the exposure of direct sunlight and help maintain lower temperatures.

Whitewashing does help with lowering the temperature associated with long exposure to summer sunlight. However it also lowers the quality of UV light reaching the plant's surface.

A greenhouse is the most effective way to control the plant's environment. However, the appropriate systems must be provided into the mix to maintain the most desirable plant growing conditions. The TrueFog Industrial Climate Control System works in several ways to create this optimum environment.

First, it cools the air. As the artificial fog evaporates, heat calories are extracted from the dry air in the process. The cool air is heavier than the hotter air and thus will fall. The hotter air, like that in a hot air balloon will rise. This exchange of hot and cold air creates proper vertical ventilation and brings more CO2 into contact with the stomata and facilitates the carbon dioxide / oxygen exchange much faster than stagnant air.

By adding humidity to the air, the TrueFog System will decrease the humidity variance between the air and plant thus lowering the demand for moisture from the plant from the air. This will drastically lower the plant's water stress and allow it to grow properly.

Lastly, by cooling the air as well as refracting some of the light which enters the greenhouse, the need for white washing will be reduced or eliminated while still allowing quality light at the proper levels to reach the plant.

By using the TrueFog Industrial Climate Control System, your plants will receive all of the above benefits of a controlled environment. When the conditions are kept at constant optimum levels, the plants stomata will stay open for longer amounts of time to absorb more carbon dioxide causing them to grow faster.

The main differences between the TrueFog System and the common alternative which is a pad and fan system are vast. The pad and fan method uses a fan to blow air over a sponge-like pad saturated with water. In theory, the fan causes the water to evaporate and circulates the moist air throughout the greenhouse. The problem with this system, however, is that it can cause some areas away from the pad to not receive much moisture while areas close to the pad will get perhaps too much moisture which can cause fungal growth. This problem can be lessened by increasing the number of pads and fans throughout the greenhouse but this solution can increase your costs and maintenance time.

The TrueFog System on the other hand, distributes the moisture-rich air evenly through the entire growing area. Also, since the system is installed overhead, mostly all of the fog droplets have evaporated before reaching the plant surface. Thus, the desired effect is reached, the cooler air falls creating the vital vertical mixing of air which facilitates the CO2 exchange, and in turn, growth.

Some problems associated with the system include condensation within the greenhouse, if the output of the system is not balanced with natural climate changes in the greenhouse. Condensation occurs when the overall temperature in the greenhouse cools in relation to the humidity in the air. This can occur in the evening and overnight while the sun is down. If the air is full of humidity and the temperature is not hot enough for it to evaporate, the moisture will fall and collect on surfaces in the form of condensation.

This problem can also be easily avoided by running the climate control system on a timed setting to release the most moisture during times of higher heat and lower humidity and release no humidity as the greenhouse temperature lowers to the point where it can no longer evaporate the moisture output.

Another problem that the greenhouse manager must consider is nozzle blockage. Nozzle blockage is a result of water mineral deposit build-up. This can be easily corrected however, by a mineral deposit inhibitor which is run through the system at scheduled intervals to clear out the deposits in the nozzles. Also, the high pressure with which our TrueFog System operates allows for longer periods of time between removal of the mineral build-up than many conventional misting modules available on the market today. The water is forced through the nozzles at such a high rate of pressure it is more difficult for the deposits to accumulate in relation to some models which are attached to simple pumps which operate at a lower efficiency rate. At any rate, individual nozzles are relatively inexpensive, and can be easily replaced without major disruption of the TrueFog System's Functioning.

Lastly, for the TrueFog Industrial Climate Control System to work efficiently and as it is intended, the greenhouse must be in areas where humidity of the outside air is generally average to low. Remember, the system requires that the air be relatively dry for the fog to evaporate while still in the air.

In speaking to many greenhouse managers and owners, I have noticed a large percentage are concerned with possible difficulties in operating such a large investment. With so many variables to consider-temperature, humidity, light, carbon dioxide, oxygen, many are concerned with experiencing complications in getting the mix just right. However, once the system is installed and operational, and after some minor adjustments during early operation, the system basically runs itself. Scheduled maintenance is recommended and should be performed regularly to keep your system running smoothly.

Even with these concerns, the greenhouse manager will realize that the TrueFog Industrial Climate Control System is capable of a wide range of uses and can correct many environmental problems that you may be experiencing now. It's relatively simple maintenance and inexpensive upkeep as well as it's various applications should prove that most greenhouses will benefit by the use of a TrueFog System. By managing the system effectively it can produce an overall positive effect on your entire crop.

HUMIDIFICATION

.jpg) INDUSTRIAL HUMIDIFICATION:

INDUSTRIAL HUMIDIFICATION:PROBLEMInstalling conventional air conditioning in warehouses can be prohibitively expensive, both in equipment and operating costs. SOLUTIONThe TrueFog, USA® warehouse cooling systems are an inexpensive, cost effective solution to cooling and humidifying warehouses throughout the world.

Using a combination of cooling tubes and standard nozzle lines, a precision system can be designed for any warehouse or factory facility. These systems are easy to install and maintain and come complete with a detailed installation manual.Optional temperature sensors are available, allowing the user to have complete control over the air temperature and humidity levels within the facility.

SPECIAL EFFECTS

SPECIAL EFFECTS and THEME PARKSPROBLEM

To create "smoke" or "fog," theme parks and movie studios have often had to resort to chemicals or oils to produce the required special effect.SOLUTIONThe TrueFog system offers a safe alternative to these methods. Using only high-pressure water, our systems create the required atmosphere with no discomfort or possible injury to spectators or actors.Utilizing water at 1,000 PSI (75 Bar), TrueFog produces ultra fine mist droplets that float freely in the air and create a fog or mist wherever required. Pure water fog is safe and economically viable to create the theme or scene desired.

For permanent installations the TrueFog system is installed using flexible nylon lines with adjustable patented fog nozzles strategically placed to give the right atmosphere and effect. Valving arrangements allow the system to be started or pulsed whenever needed either using TrueFog control system or by the designers own equipment. TrueFog engineers can specifically design each application according to your needs.

To create "smoke" or "fog," theme parks and movie studios have often had to resort to chemicals or oils to produce the required special effect.SOLUTIONThe TrueFog system offers a safe alternative to these methods. Using only high-pressure water, our systems create the required atmosphere with no discomfort or possible injury to spectators or actors.Utilizing water at 1,000 PSI (75 Bar), TrueFog produces ultra fine mist droplets that float freely in the air and create a fog or mist wherever required. Pure water fog is safe and economically viable to create the theme or scene desired.

For permanent installations the TrueFog system is installed using flexible nylon lines with adjustable patented fog nozzles strategically placed to give the right atmosphere and effect. Valving arrangements allow the system to be started or pulsed whenever needed either using TrueFog control system or by the designers own equipment. TrueFog engineers can specifically design each application according to your needs.

Heat Stress Study

HEAT KILLS PRODUCTIVITY

Perhaps you already know how much high temperatures are costing your business. If not, you may be interested in what NASA found out when they conducted their own study, CR-1205-1, "A Compendium of Human Responses to the Aerospace Environment".This definitive report shows a strong correlation between the effective temperature and human productivity. At 85 degrees, work output drops by 18% while accuracy suffers by 40%!

While productivity is the most obviously costly product of a hot, uncomfortable work environment, that's not the end of it. Your bottom line also suffers from:

Low Morale, caused by heat discomfort

Tardiness and Absenteeism

Turn over and the associated training and discharge costs

Reduced attention to Safety

Potential Health Issues

What does 18% of your payroll cost per month? Or 29%... or 45%? If you consider payback as an important factor in your equipment buying decisions, you cannot ignore the importance and value associated with providing your employees a comfortable work environment.

Perhaps you already know how much high temperatures are costing your business. If not, you may be interested in what NASA found out when they conducted their own study, CR-1205-1, "A Compendium of Human Responses to the Aerospace Environment".This definitive report shows a strong correlation between the effective temperature and human productivity. At 85 degrees, work output drops by 18% while accuracy suffers by 40%!

While productivity is the most obviously costly product of a hot, uncomfortable work environment, that's not the end of it. Your bottom line also suffers from:

Low Morale, caused by heat discomfort

Tardiness and Absenteeism

Turn over and the associated training and discharge costs

Reduced attention to Safety

Potential Health Issues

What does 18% of your payroll cost per month? Or 29%... or 45%? If you consider payback as an important factor in your equipment buying decisions, you cannot ignore the importance and value associated with providing your employees a comfortable work environment.

Odor Control ควบคุมกลิ่น

Industrial Odor Control

Industrial Odor ControlOdorLogic is a breath of fresh air for your employees, your neighbors and your community.OdorLogic developed as A Natural Organic Odor Neutralizer is a broad-spectrum odor neutralizer. It controls the full spectrum of odors (eliminating the need for multiple odor control products), and breaks them down for complete odor removal, leaving no peripheral odors or odorous byproducts.Data from independent laboratories and researchers proves that OdorLogic is:

Effective for both organic and inorganic odors

+Safe for humans

+Safe for animals

+Safe for the environment

There is a major difference between odor neutralizers and simple masking agents. If you’ve ever entered a public restroom and smelled the overpowering scent of cherry, you’ve been exposed to a masking agent. A masking agent is not effective for removing odor: it merely covers it up with another, stronger odor. When the masking agent wears off, the malodors become noticeable again. Or, while removing odor, they may introduce hazardous compounds into the very areas they “clean.”OdorLogic is an odor neutralizer. It neutralizes malodors, performing complete odor removal from the air and making it unavailable for the olfactory senses to pick up. So what you smell is… nothing.Broad-spectrum use eliminates the need for multiple odor control products—saving you money. OdorLogic eliminates the need for multiple odor control products. It is effective against both organic and inorganic malodors. We have worked with facilities experiencing a wide variety of problems and have engineered an odor control system solution to their problems—often at less cost than noncompliance fines, add-on equipment such as scrubbers, and completely new systems like a wastewater treatment plant.Furthermore— time, complaints, and noncompliance with governmental regulations cost you money and community good will. During the odor removal process, OdorLogic is used anywhere from a straight solution to a 600:1 dilution depending on the application and strength of the malodors. This flexibility in dilution rates, combined with our extensive range of application equipment, enables us to provide you with the most cost-effective odor control system possible.OdorLogic is safe it is nontoxic, non-hazardous, biodegradable, and contains no harmful Chemicals:OdorLogic is safe for both workers and the environment. It consists of natural organic compounds, food grade surfactants, and purified water.

OdorLogic is revolutionizing industries that deal with malodor problems—whether it be year-round, seasonal or application-based. OdorLogic doesn't simply mask odor with other fragrances or harsh chemicals. Instead, it breaks down and removes a full spectrum of both organic and inorganic odors—leaving your workers, your neighbors and your community with a breath of fresh air. It's safe. It's powerful. It's cost effective. And it's available to you.

OdorLogic was originally developed to be effective on a broad range of problematic odors. The mechanisms through which the products perform are complex—however, the fundamental mechanisms are adsorption, absorption, gas solubility and distribution constant enhancement, and reaction.OdorLogic is most often diluted with water and applied via TrueFog, USA atomization systems as an aerosol into process air. The mix in these droplets separate with the oils forming a thin film over the water droplet itself. This skin creates an electrostatic charge over its outer surface that facilitates adsorption of the malodor molecules onto the droplet surface. With adsorption comes then absorption where the gas is taken up by the droplet (solubility) and held. At this point the malodor is under control. Studies have shown that with many acidic and basic gasses a reaction takes place after the gas has been captured within the droplet. This reaction with the mild buffer contained within OdorLogic tends to yield harmless organic salts.Laboratory studies have proven that OdorLogic enhances the solubility of most gasses. This absorption, or solubility mechanism, coupled with the adsorption phenomena facilitates a gas uptake increase well over the amount of gas the buffer within the product can neutralize. The same laboratory studies show the product enhances the distribution constant of the captured gas, meaning the aqueous OdorLogic solution will give less of the captured gas back into the atmosphere out of the aerosol droplet. In this way, OdorLogic is able to neutralize odors of gasses with which it will react and with those with which it will not react. The non-reacting gasses tend to be the neutral hydrocarbons such as styrene.

TrueFog is the simplest and most effective method of removing odors from manufacturing, industrial and waste handling treatment sites. TrueFog odor control systems provide a safe and economical method of eliminating a wide range of odor problems.

Combined with OdorLogic odor-neutralizing materials for both interior and exterior applications. TrueFog is particularly effective with all natural neutralizing products, a blend of all-natural oils including peppermint, lemon and eucalyptus, is a highly effective odor neutralizer in even the most difficult odor control situations.

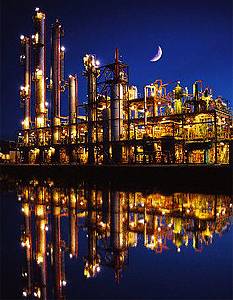

Spread over wide areas by the TrueFog System, OdorLogic will kill odors at everything from landfills and garbage dumps to stock yards and waste water treatment plants. The odor control system is equally effective against the offensive odors produced at industrial sites such as refineries, rendering plants, pulp and paper mills, and waste transfer and recycling stations.

Completely harmless — all OdorLogic odor control compounds used are either food or cosmetic grade, with a long history of safety in use. TrueFog works the way nature works, It is not a masking agent.

Released into the atmosphere, TrueFog attaches itself to malodor molecules via natural forces, increasing the overall molecular mass. This forces the molecule down to a lower atmospheric level where it is broken down naturally.

TrueFog spreads across large areas, keeping the neutralizer suspended until it encounters odors. The two elements then combine to form a neutral substance that turns into particulate and falls away harmlessly.

Custom Designed, lightweight and compact TrueFog provides a unique system that can be controlled completely automatically, 24 hours a day. TrueFog can be set up in hours, quickly alleviating complaints from neighbors as well as improving on-site working conditions.

INDUSTRIAL APPLICATIONS

• Aeration Ponds

• Air Scrubbers

• Air Handling Equipment

• Chemical Manufacturing

• Composting

• Industrial Exhaust

• Lift Stations

• Kennels, Animal Shelters

• Landfills, Garbage Dumps

• Liquid Waste Wells

• Wet Ponds

• Meat Packers

• Rendering Plants

• Oil Sludge Cleanup

• Poultry & Livestock

• Pulp & Paper Mills

• Recycling Centers

• Refineries

• Sludge & Slurry Handling

• Solid Waste Management

• Stockyards

• Waste Transfer Stations

• Waste Water Treatment

สมัครสมาชิก:

บทความ (Atom)